Burnt Orange Color Spray Paint: Vibrant Makeovers!

In the world of DIY projects and professional endeavors, the choice of color significantly impacts the look and feel of any creation.

Burnt orange color spray paint, renowned for its deep, warm hues, stands out as a favorite among enthusiasts and professionals for its ability to infuse projects with a sense of energy and innovation. From accent walls to furniture, the versatility of burnt orange can transform any space into a vibrant sanctuary. For those seeking inspiration, exploring burnt orange wall color ideas can help envision how this striking hue pairs beautifully with other colors and textures. Whether used in a contemporary setting or a more traditional environment, burnt orange adds warmth and character that is hard to replicate.

This guide aims to navigate you through the essentials of selecting, applying, and perfecting the application of burnt orange spray paint, ensuring your projects not only stand out but also reflect the highest quality of workmanship.

Selecting the Right Brand

Surface Preparation

Application Techniques

Safety Measures

For a DIY project like revamping an old wooden chair, burnt orange spray paint can transform it into a vibrant, statement piece.

Start by cleaning and sanding the chair, apply a primer, and then proceed with the burnt orange spray paint, following the application techniques mentioned above. The result will be a beautifully rejuvenated chair that adds a pop of color to any room.

In transforming your projects with burnt orange spray paint, remember that the beauty lies in the details.

A little effort in preparation and application goes a long way in achieving professional, eye-catching results.

Key Takeaway

Understanding Burnt Orange

Burnt orange, a deep, warm hue that seamlessly blends red and orange tones, stands as a versatile color in both design and decorative applications, encapsulating a sense of earthiness and sophistication.

Its rich saturation offers a dynamic visual impact, making it a favorite among designers aiming to evoke strength, endurance, and comfort within a space.

When translated into spray paint, this color retains its depth and vibrancy, providing a robust medium for creative expression.

The formulation of burnt orange spray paint involves a meticulous balance of pigments to achieve its signature warmth and depth.

This process underscores the importance of precision in achieving the desired effect, highlighting the technical intricacies behind replicating this complex color in a sprayable form.

Choosing the Right Brand

Selecting an appropriate brand of burnt orange spray paint is crucial, as it ensures the color’s integrity and durability on various surfaces.

When choosing the right brand, consider the following factors:

- Pigment Quality: High-quality pigments provide vibrant, long-lasting colors that resist fading over time.

- Adhesion: Look for brands that offer excellent adhesion to a wide range of materials, ensuring the paint stays put without peeling or chipping.

- Drying Time: A faster drying time can significantly speed up your project, but it shouldn’t compromise the paint’s finish or durability.

- Environmental Impact: Innovative brands now offer low-VOC or VOC-free options, which are better for both the environment and the user’s health.

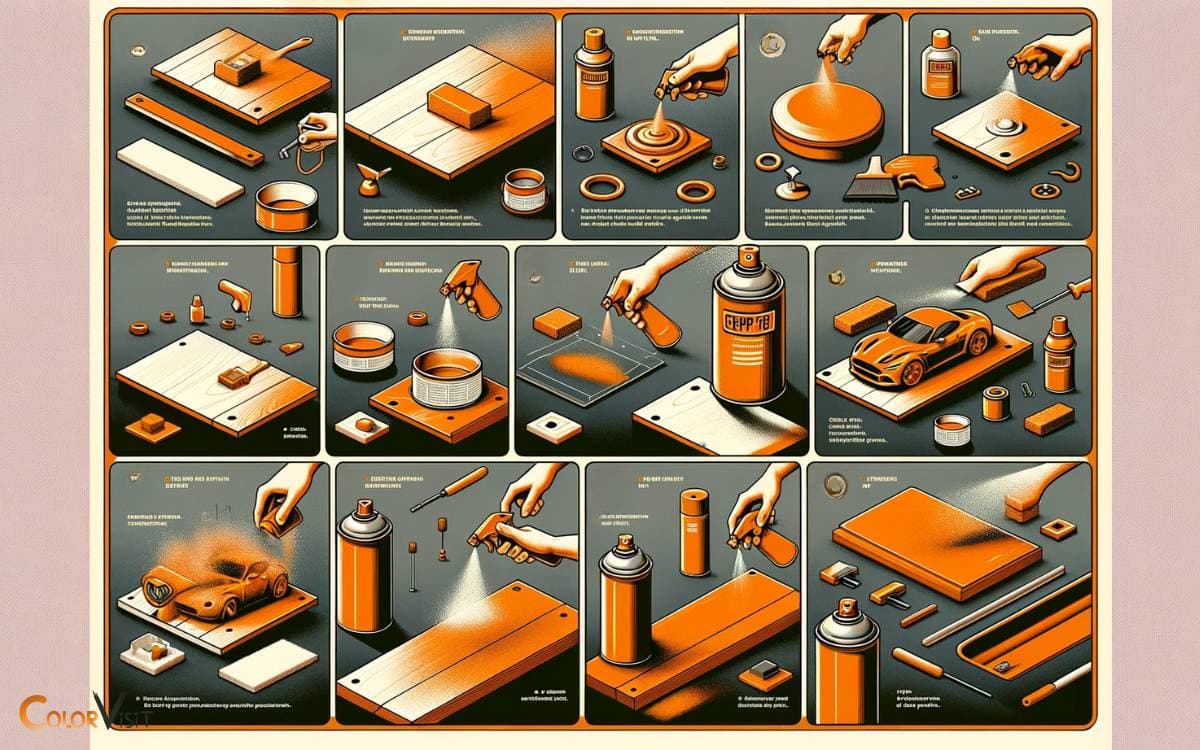

Preparing Your Surface

Prior to applying burnt orange color spray paint, it is essential to adequately prepare the surface to ensure optimal paint adhesion and finish.

This preparation involves thorough cleaning of the surface to remove any contaminants, followed by the application of a suitable primer.

These steps are critical for achieving a durable and aesthetically pleasing outcome.

Surface Cleaning Tips

For optimal adhesion of burnt orange color spray paint, thorough surface cleaning is an essential preparatory step.

Ensuring the surface is impeccably clean not only enhances the paint’s adherence but also contributes to a flawless finish.

Here are critical cleaning steps to prepare your surface:

- Dust Removal: Use a soft brush or cloth to remove all surface dust, which could impair paint bonding.

- Grease and Oil Elimination: Apply a degreaser to remove any oily residues that can prevent paint from sticking effectively.

- Mildew Treatment: If applicable, use a solution designed to kill mildew, ensuring the surface is free from biological growths.

- Rinsing: After cleaning, thoroughly rinse the surface with clean water to remove any residual cleaning agents, ensuring a neutral base for painting.

Priming Before Painting

After ensuring the surface is thoroughly cleaned, the next critical step in preparing for the application of burnt orange color spray paint involves applying a suitable primer to enhance paint adhesion and achieve a uniform finish.

Primer serves as an intermediary layer that ensures the paint adheres better to the surface, preventing flaking and increasing durability.

For optimal results, select a primer specifically formulated for the material being painted, whether it be metal, wood, or plastic.

Application techniques vary; however, a light, even coat is typically recommended to create a smooth, receptive surface for the burnt orange hue.

Allow the primer to dry completely, following the manufacturer’s recommended drying time, before proceeding with the spray paint application. This preparation step is vital for a professional, long-lasting finish.

Application Techniques

To ensure an even and smooth finish when applying burnt orange color spray paint, it is essential to master the correct techniques.

The precision in application not only enhances the aesthetic appeal but also ensures the longevity of the paint job.

Here are four crucial steps:

- Shake Vigorously: Before application, shake the can for at least 2 minutes to ensure the paint is well mixed.

- Test Spray: Always perform a test spray on a scrap material to check for color consistency and spray pattern.

- 45-Degree Angle: Hold the can approximately 6-8 inches away from the surface, and spray in a steady back-and-forth motion, maintaining a 45-degree angle.

- Multiple Thin Coats: Apply several thin coats rather than a single thick coat, allowing adequate drying time between applications. This technique prevents drips and ensures a uniform color finish.

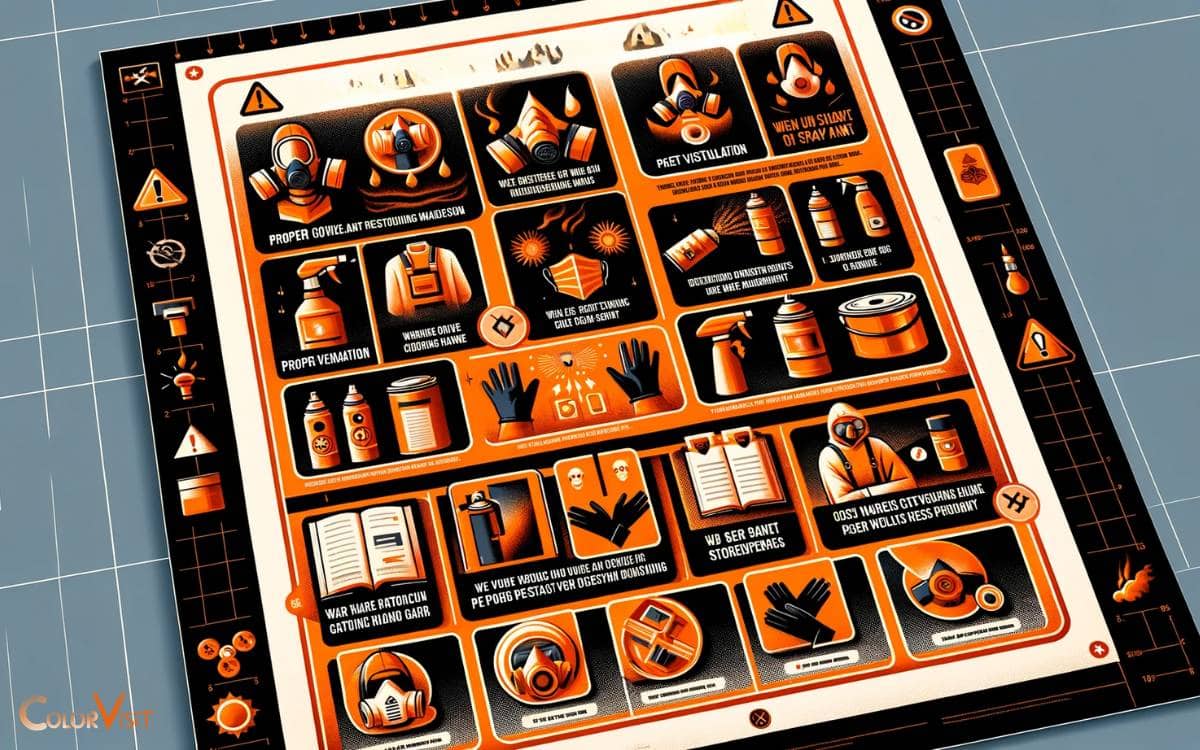

Safety Measures

While employing burnt orange color spray paint, it is imperative to adhere to specific safety measures to mitigate health risks and ensure a safe working environment.

Utilization of personal protective equipment (PPE) is non-negotiable; this includes respirators approved for paint fumes, gloves, and safety goggles to prevent inhalation of toxic substances and protect against chemical splashes.

Working in a well-ventilated area is paramount to disperse harmful vapors, minimizing the inhalation risk.

Furthermore, grounding oneself in the knowledge of the paint’s chemical composition is crucial, as it informs the necessary precautions against potential chemical reactions and fire hazards.

Adhering to these guidelines not only promotes health and safety but also enhances the efficiency and quality of the project outcome.

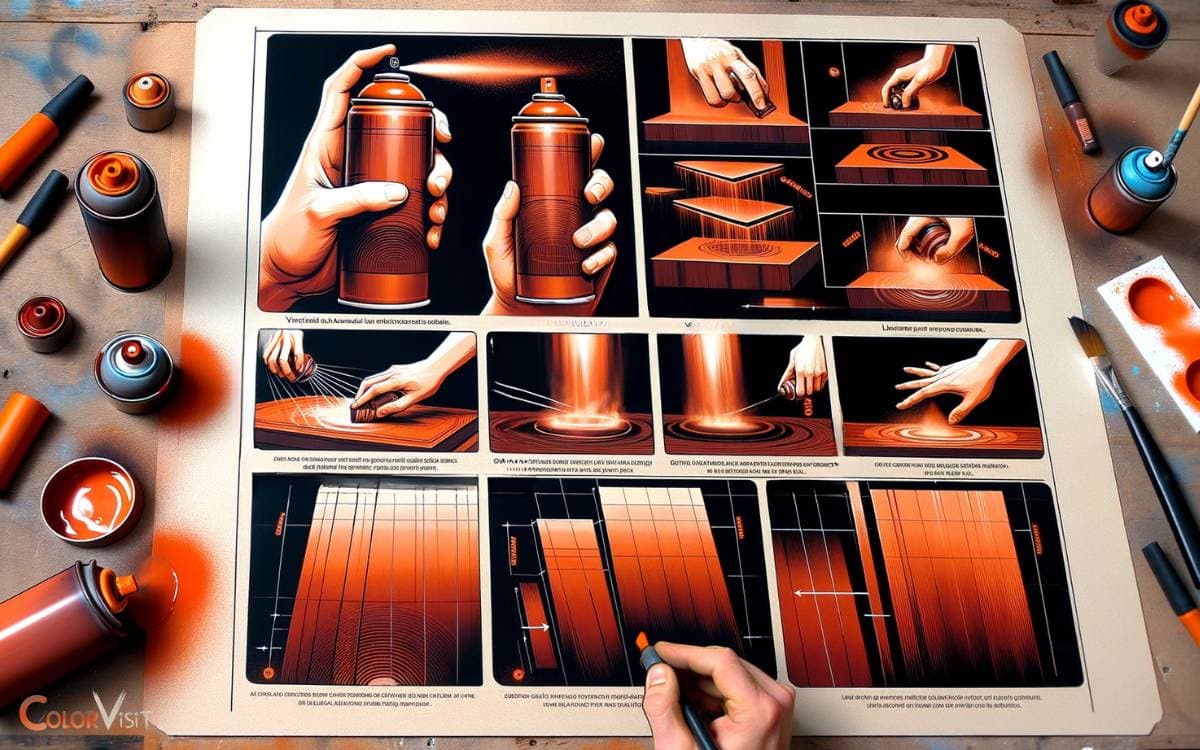

Achieving Even Coverage

Achieving even coverage with burnt orange color spray paint necessitates meticulous attention to detail across several key processes.

Initially, proper surface preparation is paramount to ensure the paint adheres evenly and smoothly.

Following this, mastering the optimal application technique and adhering to specific drying and reapplication guidelines will significantly enhance the final appearance and durability of the painted surface.

Surface Preparation Steps

Preparing the surface meticulously is crucial for ensuring even coverage when applying burnt orange color spray paint.

The following steps are instrumental in achieving a finish that not only looks professional but also lasts longer:

- Cleaning: Remove all dirt, grease, and dust from the surface using a degreaser or soapy water. Allow it to dry completely.

- Sanding: Use fine-grit sandpaper to lightly sand the surface. This will create a slightly rough texture for better paint adhesion.

- Dusting: Wipe off the sanding dust with a clean, damp cloth to ensure a clean surface for painting.

- Priming: Apply a suitable primer to enhance paint adhesion and to ensure that the true color of the burnt orange paint is achieved upon application.

Optimal Application Technique

For optimal results in applying burnt orange color spray paint, mastering the correct application technique is essential for ensuring even coverage and a flawless finish.

Begin by holding the can approximately 6 to 8 inches away from the surface, maintaining a steady, controlled motion to prevent drips and uneven layers.

Utilize a horizontal back-and-forth motion, slightly overlapping each pass to cover the surface comprehensively without creating thick sections.

This method, known as the 50/50 rule, is critical for achieving uniformity. It’s also advisable to apply multiple thin coats rather than a single thick coat, allowing for more precise control over the opacity and finish.

Adhering to these guidelines will significantly enhance the application process, leading to a professional and aesthetically pleasing outcome.

Drying and Reapplication Tips

Understanding the importance of proper drying times and reapplication methods is essential for ensuring even coverage when using burnt orange color spray paint.

To achieve optimal results, consider the following guidelines:

- Allow Adequate Drying Time: Wait for the first coat to dry completely before applying subsequent layers. This prevents smudging and ensures a smooth, even finish.

- Apply Thin, Even Coats: Multiple light coats are preferable to a single heavy coat. This technique reduces the risk of drips and ensures uniform color saturation.

- Monitor Environmental Conditions: Humidity and temperature significantly affect drying times. Work in a well-ventilated, temperate environment to facilitate even drying.

- Inspect and Touch-Up: After the final coat has dried, carefully inspect the surface for any inconsistencies. Apply touch-ups as needed to achieve flawless coverage.

Drying and Curing Time

The drying and curing time for burnt orange color spray paint typically varies based on factors such as ambient temperature, humidity, and the thickness of the applied coat.

Under optimal conditions, with low humidity and temperatures around 70°F (21°C), the initial drying phase can take as little as 20 minutes to an hour for touch dryness.

However, for a fully cured finish, a period of 24 to 48 hours is advisable. It’s imperative to note that thicker coats extend the curing process, necessitating patience and precision in planning reapplication or handling the painted object.

Innovatively designed formulae aim to reduce wait times while ensuring durability, yet environmental conditions remain a critical determinant.

Adhering to specified durations ensures the longevity and resilience of the finish, embodying innovation in application and final presentation.

Finishing Touches

Applying the final finishing touches to a burnt orange color spray paint project often necessitates a meticulous approach to achieve a polished and durable surface.

This phase is critical for enhancing both the aesthetic appeal and longevity of the finish.

- Sand the Surface Lightly: Use ultra-fine sandpaper to gently smooth any imperfections, ensuring a flawless base for further coatings.

- Apply a Clear Sealant: Choose a high-quality, UV-resistant clear coat to protect the paint from fading, chipping, or peeling.

- Buff for Gloss: If a glossy finish is desired, carefully buff the surface with a microfiber cloth after the sealant has fully cured.

- Inspect for Consistency: Examine the project in various lighting conditions to ensure color and finish uniformity, making minor adjustments as necessary.

These steps encapsulate the precision required to realize an innovative and enduring burnt orange finish.

Maintenance Tips

Maintaining a burnt orange color spray paint finish requires regular attention to detail and adherence to specific care practices to preserve its vibrancy and durability.

To ensure longevity, it is essential to apply a UV-resistant clear coat to protect the color from fading under sunlight.

Regular cleaning with a soft, damp cloth can prevent dust accumulation, which might dull the finish over time. Avoid using harsh chemicals or abrasive materials that could compromise the integrity of the paint layer.

For outdoor applications, consider a periodic reapplication of the topcoat to combat environmental stressors such as moisture and temperature fluctuations.

Implementing these maintenance tips will safeguard the aesthetic appeal and structural integrity of burnt orange spray-painted surfaces, ensuring they remain a focal point of innovation and creativity.

Creative Project Ideas

Utilizing burnt orange color spray paint, individuals can embark on a variety of creative projects that transform ordinary objects into vibrant pieces of art.

This hue, with its deep warmth and richness, can add a unique touch to both indoor and outdoor projects. When approached with innovation in mind, the possibilities become nearly endless.

Here are four project ideas to inspire your next creation:

- Refurbishing Vintage Furniture: Add a modern twist to an old piece by applying a burnt orange finish.

- Custom Wall Art: Create abstract or geometric patterns on canvas or wood panels.

- Decorative Planters: Give your garden a pop of color by spraying terracotta pots.

- Accent Pieces: Transform lamp bases or picture frames for an updated look.

These projects demonstrate the versatility and transformative power of burnt orange spray paint, offering a palette for innovation and creativity.

Troubleshooting Common Issues

In utilizing burnt orange color spray paint, users may encounter specific challenges such as spray paint runs, a dull color finish, or a clogged nozzle.

Addressing these issues requires a systematic approach to identify the underlying causes and implement effective solutions.

This section will provide insights and methodologies to rectify these common problems, ensuring optimal results in spray paint applications.

Spray Paint Runs

Spray paint runs, characterized by drips or streaks that mar the finish, often result from improper application techniques or environmental conditions.

To mitigate these issues and achieve a flawless burnt orange finish, consider the following steps:

- Maintain Optimal Distance: Hold the spray can approximately 6 to 8 inches away from the surface to ensure even coverage and prevent runs.

- Apply Multiple Thin Coats: Rather than a single thick coat, apply several thin layers, allowing adequate drying time between applications.

- Control Environmental Conditions: Work in a well-ventilated area free from dust and humidity, which can affect paint adhesion and drying.

- Perfect Your Technique: Use a steady, sweeping motion to apply paint, avoiding the temptation to linger in one spot, which can cause runs.

Dull Color Finish

A dull color finish, often resulting from inadequate surface preparation or incorrect application methods, can significantly detract from the aesthetic appeal of burnt orange spray paint projects.

Ensuring a vibrant, lasting color involves meticulous preparation of the surface. This includes thorough cleaning to remove any oils, dirt, or rust that may impede the paint’s adherence and shine.

Equally critical is the application technique; uniform, thin coats are paramount to preventing the absorption of light, which contributes to a matte appearance.

Additionally, environmental factors such as humidity and temperature play a crucial role in the drying process, affecting the final sheen.

Strategic adjustments to these variables can mitigate the risk of a dull finish, thereby enhancing the visual impact of the painted item.

Clogged Nozzle Solutions

While meticulous preparation and application techniques are essential for achieving a vibrant finish, addressing clogged nozzles is critical for maintaining the quality and consistency of burnt orange spray paint projects.

Implementing effective solutions can mitigate this issue, ensuring a smooth and even application.

Here are four strategies:

- Soak the Nozzle: Submerge the clogged nozzle in a solvent like acetone or paint thinner for several hours to dissolve the dried paint.

- Use a Needle: Carefully insert a thin needle or pin into the nozzle hole to dislodge any paint residue.

- Replace the Nozzle: If cleaning fails, replace the nozzle with a new one from a similar can or a universal replacement.

- Preventive Measures: Always clear the nozzle after use by inverting the can and spraying until clear gas comes out.

Environmental Considerations

Environmental impacts associated with burnt orange color spray paint necessitate a thorough analysis of its production, application, and disposal processes.

The production phase often involves the emission of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), which contribute to air quality degradation and pose health risks.

During application, the aerosol dispersal mechanism leads to particulate matter distribution, affecting both indoor and outdoor environments.

Proper disposal is paramount to prevent chemical leaching into soil and water bodies, highlighting the need for recycling programs and hazardous waste management protocols.

Innovations in eco-friendly formulations and packaging designs aim to mitigate these environmental concerns, offering solutions such as water-based alternatives and biodegradable containers to reduce the ecological footprint of spray paint products.

Where to Buy

Identifying reputable retailers that offer burnt orange color spray paint is essential for consumers seeking quality and environmentally responsible options.

These retailers not only provide high-grade products but also align with the innovative needs of the market.

To assist in your search, consider the following avenues:

- Specialty Paint Stores: Known for their vast selection and expert advice, these stores often carry premium, eco-friendly spray paint options.

- Online Marketplaces: Platforms like Amazon and eBay offer a wide range of products, including specialized paint colors and environmentally safe options.

- Hardware Stores: Major chains such as Home Depot and Lowe’s stock a variety of spray paints, including burnt orange, with an emphasis on quality and durability.

- Art Supplies Stores: These retailers cater to creative professionals and hobbyists, offering high-pigment options for detailed work.

Conclusion

The journey of utilizing burnt orange color spray paint encompasses:

- A meticulous selection of the appropriate brand

- Rigorous preparation of the surface

- Adept application techniques

- Stringent adherence to safety protocols

- Exploration of creative project ideas

- Adept troubleshooting of common issues

- Consideration of environmental impacts

- Strategic procurement of supplies.

This odyssey, akin to navigating the labyrinth of Daedalus, requires precision, caution, and creativity, ultimately leading to the successful embellishment of objects with this vibrant hue.