How Do Red Skittles Get Their Color? FDA-Approved!

Red Skittles get their vibrant color from food dyes specifically Red 40, a FDA-approved artificial food coloring.

This dye is meticulously selected and mixed into the candy during the manufacturing process, resulting in the iconic red Skittle.

The color of red Skittles is achieved through the use of Red 40, a common food dye.

This artificial coloring is mixed with the other ingredients in precise quantities to produce the bright red color. The process involves a strategic blend of science and artistry.

For example, during Skittles production:

The captivating red hue of Skittles is an iconic symbol of the candy’s fun and vibrant character.

This signature color is a testament to the meticulous process and quality control measures involved in candy-making.

Key Takeaway

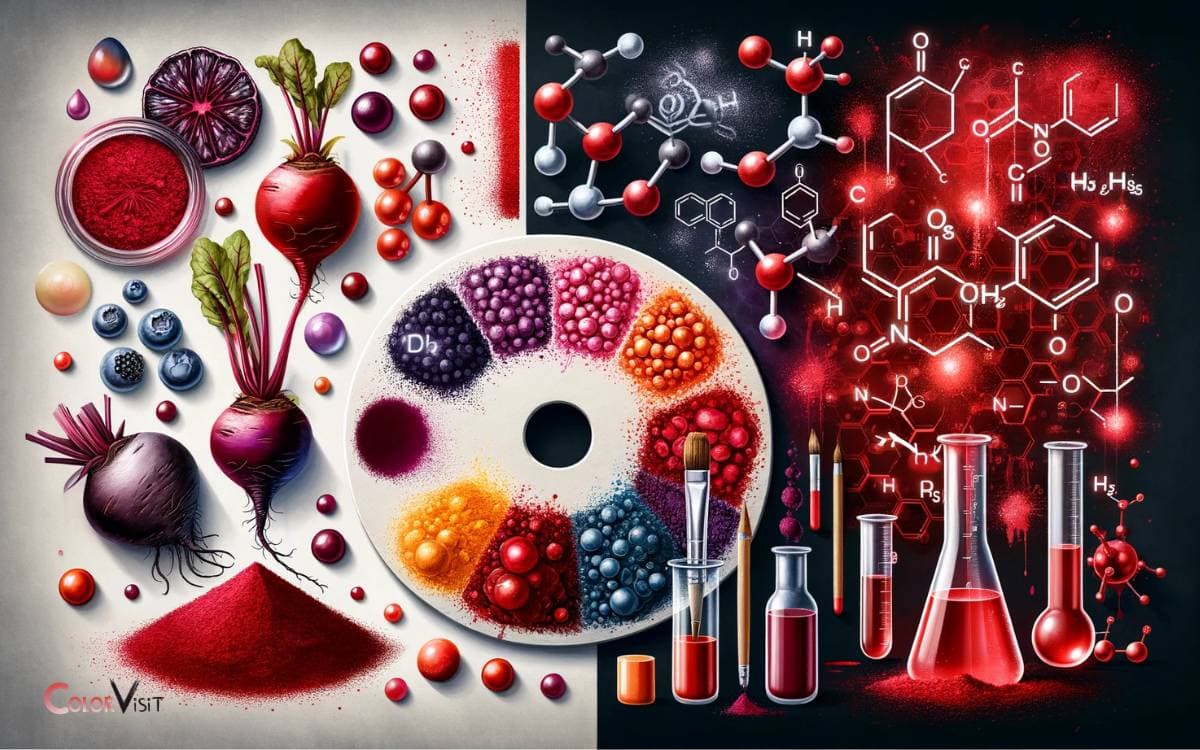

The Science of Red Dyes

The science of red dyes is a fascinating area of study that delves into the molecular structures and chemical processes responsible for producing the vibrant red color seen in various food products such as Skittles.

- Color perception plays a crucial role in the way red dyes are perceived by consumers.

- The chemical composition of red dyes, particularly the presence of compounds such as anthocyanins or carotenoids, determines their ability to reflect and absorb specific wavelengths of light, resulting in the perception of the color red.

- Understanding the intricate chemical composition of red dyes allows for the precise formulation of these dyes, ensuring that the desired vibrant red hue is achieved consistently in food products.

This scientific approach to red dyes enables innovation in creating visually appealing and marketable food items.

Natural Vs. Artificial Coloring

Red Skittles get their red color from a combination of natural and artificial colorings.

- The use of natural coloring, such as carmine (derived from the cochineal insect), provides a vibrant red hue, while artificial colorings, like Red 40, offer consistency and stability.

- The debate between natural and artificial coloring revolves around health concerns. While natural coloring may appeal to health-conscious consumers due to its plant or insect origins, it can still cause allergic reactions in some individuals.

On the other hand, artificial colorings have been linked to hyperactivity in children and other potential health risks.

Here’s a comparison of natural and artificial colorings:

| Aspect | Natural Coloring | Artificial Coloring |

|---|---|---|

| Source | Plants, Insects | Synthetic chemicals |

| Health Concerns | Allergic reactions, potential natural toxins | Hyperactivity, potential carcinogenic properties |

Blending the Perfect Shade

The process of blending the perfect shade involves several steps. First, red dye is sourced from both natural and artificial sources.

This dye is then carefully mixed to achieve the desired hue. It is important to follow a precise color mixing process to ensure the shade is perfect.

Quality control measures are also crucial during this process. These measures help to ensure consistency and adherence to color specifications.

By implementing quality control, manufacturers can guarantee that each shade produced is of the highest quality.

Red Dye Sources

Acquiring just the right shade of red for Skittles involves carefully blending a precise combination of red dye sources.

The red dye used in Skittles can come from various sources, each with its own unique properties and considerations:

- Plant-based dyes, sustainability: Some red dyes are derived from natural sources such as beets, which offer a sustainable and environmentally friendly option for coloring Skittles.

- Chemical dyes, health concerns: Synthetic red dyes, like Red 40, can provide a vibrant and consistent color but may raise concerns regarding potential health effects. Careful consideration is required to ensure safety.

- Innovations in red dyes: Ongoing research aims to develop new, safe, and sustainable red dye sources that meet both the high color quality standards and the growing demand for healthier, more natural ingredients in consumer products.

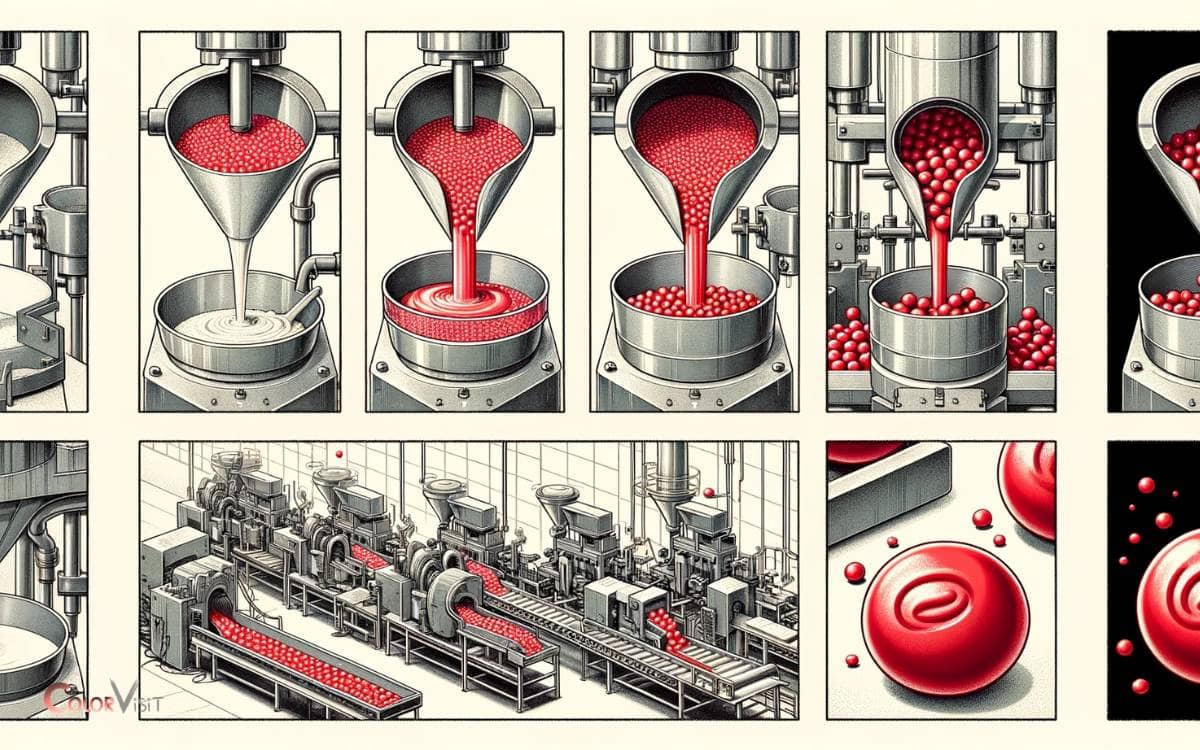

Color Mixing Process

The color mixing process for Skittles involves carefully blending a precise combination of red dye sources to achieve the perfect shade, ensuring both color quality and safety standards are met.

- This meticulous process begins with pigment selection, where various red pigments are assessed for their hue, saturation, and compatibility.

- Once the appropriate pigments are chosen, they undergo a precise color mixing procedure to achieve the desired red shade.

This involves the accurate measurement and blending of pigments in specific ratios to create the signature red color that defines Skittles.

The table below showcases some common pigments used in the color mixing process for Skittles:

| Pigment | Properties | Common Uses |

|---|---|---|

| Red 40 | Bright red shade | Confectionery |

| Carmine | Deep red hue | Food coloring |

| Allura Red | Intense red color | Beverages |

This color mixing process ensures that Skittles maintain their vibrant red color and consistent quality. Next, it’s essential to discuss quality control measures in the production of red Skittles.

Quality Control Measures

To ensure the consistent vibrancy and quality of the red Skittles, a meticulous quality control process is implemented, using precise measurements and rigorous standards to blend the perfect shade of red.

- Color Consistency: Advanced spectrophotometers are utilized to measure color accuracy, ensuring that every batch of red Skittles matches the specified hue.

- Manufacturing Processes: Cutting-edge mixing technologies and automated systems are employed to guarantee uniform distribution of color throughout the candy mixture.

- Quality Assurance Checks: Statistical process control methods are applied at various stages of production to monitor color intensity, preventing deviations from the desired red shade.

Quality Control in Coloration

Ensuring that the coloration of red Skittles meets quality standards is a critical aspect of the production process.

- Color consistency and adherence to manufacturing standards are essential to guarantee the vibrant red hue that consumers expect.

- Quality control measures in coloration involve rigorous testing and monitoring at various stages of the production line. This includes spectroscopy analysis to measure color intensity, hue, and uniformity.

- Additionally, visual inspection by trained personnel ensures any deviations from the standard are promptly identified and addressed.

The table below outlines key parameters monitored during quality control in coloration:

| Parameter | Measurement | Standard |

|---|---|---|

| Color Intensity | Spectrophotometry | Lab* values |

| Hue | Visual Inspection | Red spectrum |

| Uniformity | Image Analysis | Coefficient of Variation |

The Role of Sugar Coating

The sugar coating on Skittles plays a crucial role in binding the color to the candy surface. This process impacts the overall taste and visual appeal of the product.

Understanding how the production process influences the sugar coating is essential for maintaining quality and consistency in coloration.

Sugar and Color Binding

When discussing the color binding process of red Skittles, it is essential to understand the role of sugar coating in determining the final hue. The sugar binding process plays a crucial role in ensuring color retention and vividness in red Skittles.

This is achieved through:

- Uniform Coating: The sugar coating process ensures that each Skittle receives a uniform layer of sugar, which acts as a binding agent for the color.

- Color Stability: The sugar coating helps in stabilizing the color by protecting it from heat, light, and moisture, maintaining the vibrant red hue.

- Enhanced Gloss: The sugar coating not only binds the color but also contributes to the glossy appearance, enhancing the visual appeal of red Skittles.

This meticulous sugar binding process is fundamental in achieving the iconic red color of Skittles, ensuring consistent quality and visual appeal.

Impact on Taste

The sugar coating not only binds the color of red Skittles but also significantly influences their overall taste profile.

- The thin layer of sugar on the surface of the Skittle interacts with the taste buds on the tongue, impacting taste preferences and sensory perception.

- The sweetness of the sugar coating balances the tartness of the fruit-flavored interior, creating a harmonious blend of flavors that is appealing to consumers.

- Furthermore, the sugar coating plays a crucial role in enhancing the sensory experience by providing a satisfying crunch upon biting into the candy.

- This combination of taste and texture contributes to the overall enjoyment of red Skittles, making them a popular choice among consumers with diverse taste preferences.

Understanding the intricate relationship between the sugar coating and taste perception is essential for creating products that cater to evolving consumer demands.

Production Process Influence

The production process of red Skittles is influenced by the sugar coating, which plays a pivotal role in binding the color and enhancing the overall sensory experience of the candy. The influence of temperature and color stability are crucial factors in the production process.

Here’s how the sugar coating affects the production of red Skittles:

- Temperature Control: Precise control of temperature during the sugar coating process is essential to ensure that the red color remains vibrant and consistent.

- Color Stability: The sugar coating protects the color of the red Skittles from degrading due to environmental factors, ensuring that the candy maintains its vibrant appearance.

- Uniform Application: The sugar coating process must be carefully regulated to ensure that the red color is uniformly applied to each Skittle, maintaining visual appeal and quality.

These factors demonstrate the intricate role of sugar coating in the production of red Skittles, ensuring a consistent and visually appealing product.

Shaping the Red Skittle

Shaping the red Skittle involves incorporating the red dye into the candy mixture during the manufacturing process.

- The chemical composition of the red dye is meticulously formulated to ensure uniform distribution and vibrant coloration.

- Color psychology is leveraged to determine the precise shade of red that will most effectively appeal to consumers.

- The candy mixture, once infused with the red dye, undergoes a shaping process through a specialized molding technique.

- This technique ensures that each red Skittle achieves its iconic round shape and smooth texture.

- The precision in shaping the red Skittle is crucial in maintaining product consistency and enhancing consumer experience.

- Innovation in shaping techniques continually evolves to meet consumer demands and market trends, ensuring that the red Skittle remains a beloved confectionery choice.

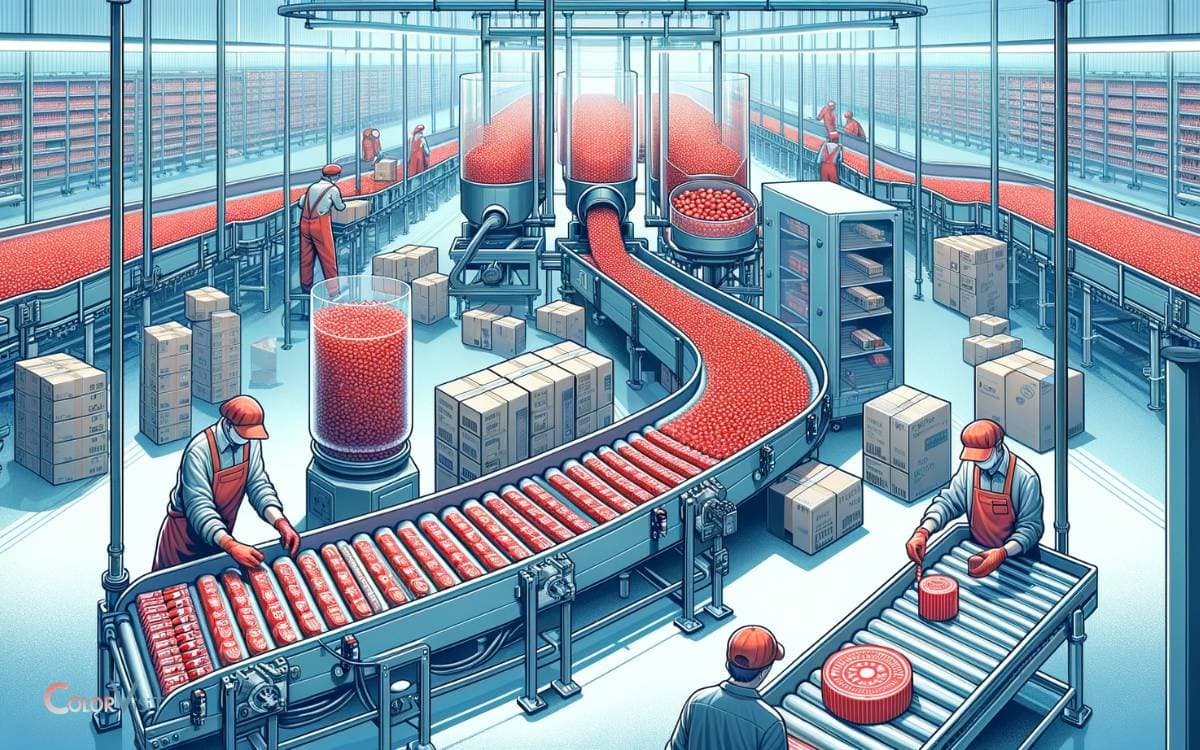

Packaging and Preservation

Packaging and preservation of red Skittles involves utilizing specialized techniques to maintain color vibrancy and extend shelf life while ensuring product integrity and consumer satisfaction.

Preservation techniques and packaging innovation play a crucial role in achieving these objectives:

- Modified Atmosphere Packaging (MAP) – This technique involves modifying the atmosphere inside the packaging to slow down the oxidation process, preserving the color and flavor of the red Skittles.

- Moisture Barrier Technology – Advanced packaging materials with moisture barrier properties prevent moisture ingress, safeguarding the texture and taste of the red Skittles.

- Oxygen Absorbers – These packets are inserted into the packaging to absorb any excess oxygen, which can lead to color fading and spoilage, thereby extending the shelf life of the product.

Conclusion

The process of coloring red Skittles involves the use of both natural and artificial dyes, as well as precise blending to achieve the perfect shade.

Quality control measures ensure consistency in coloration, and the sugar coating and shaping process play a crucial role in the final product.

Packaging and preservation methods are also essential in maintaining the vibrant red color of the Skittles. The science behind the red dye used in Skittles is truly fascinating and complex.