How Is Red Food Color Made? Natural Sources!

Red food color is primarily derived from natural sources like beets and berries or through synthetic methods using chemicals.

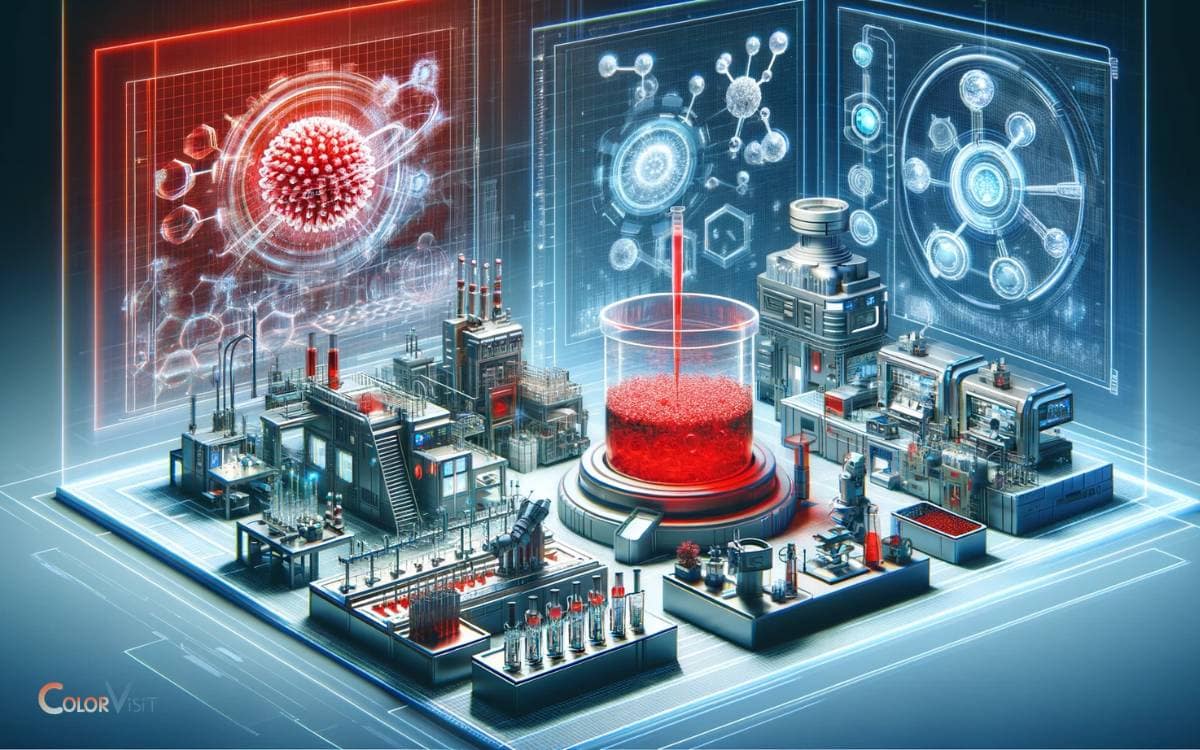

The process involves extraction, concentration, and application techniques to deliver this crucial ingredient in our food.

Through a process of extraction and concentration, the color is isolated and then used in various food products. For example, beet juice may be used to provide a red hue in ice creams or candies.

Synthetic red food coloring is chemically produced. Some of the most common synthetic red food dyes include Red No.3 (Erythrosine) and Red No.40 (Allura Red AC).

These are often used in products such as soda, candy, and baked goods due to their bright, consistent color and longer shelf-life.

Key Takeaway

The Origins of Red Food Color

The origins of red food color can be traced back to the extraction and processing of natural sources such as fruits, vegetables, and insects.

- Historically, civilizations utilized these natural sources to produce red pigments for various cultural and culinary purposes.

- The history of red food color production dates back to ancient civilizations like the Egyptians, who used red pigments in their artwork and cosmetics.

- In Chinese culture, red is a symbol of good fortune and joy, leading to the use of red food color in traditional dishes and celebrations.

- The cultural significance of red pigments is evident in Indian cuisine, where vibrant red spices like paprika and chili powder are integral to both flavor and visual appeal.

Understanding the origins and cultural significance of red food color provides valuable insight into its enduring relevance in the culinary world.

Natural Sources of Red Pigments

One major source of red pigments used in food coloring is the cochineal insect, which is commonly found in South America and Mexico.

- Other natural sources of red pigments include plant-based sources like annatto seeds, which yield a vibrant red color when processed, and red beetroot, which contains betalains responsible for its intense red hue.

- Additionally, certain fruits such as pomegranates and berries, along with vegetables like tomatoes and red peppers, are rich in red pigments that can be extracted for food coloring.

- These natural extraction methods provide a sustainable and environmentally friendly approach to obtaining red pigments for food coloring, aligning with the growing demand for natural ingredients in the food industry.

Extraction and Concentration Methods

Utilizing various extraction techniques, such as solvent extraction and supercritical fluid extraction, red pigments are isolated from natural sources like beets or berries.

- Solvent extraction involves using solvents to separate the pigments from the plant material, while supercritical fluid extraction utilizes carbon dioxide under high pressure to achieve the same purpose.

- Once the red pigments are extracted, color concentration is achieved through methods like membrane filtration or evaporation.

- Membrane filtration separates the pigments from impurities based on molecular size, while evaporation removes the solvent to increase pigment concentration.

- These techniques ensure that the red food color produced is vibrant and concentrated, meeting the high standards of the food industry for natural and synthetic colorants.

Synthetic Red Food Color Production

Scientific, detailed, and informative, the production of synthetic red food color involves a chemical synthesis process that creates the desired hue.

Safety and regulations play a crucial role in ensuring that the synthetic colorants used in food products meet strict quality and health standards.

Furthermore, understanding the applications of synthetic red food color in various food products provides valuable insight into its widespread use in the food industry.

Chemical Synthesis Process

The chemical synthesis process for red food color involves the transformation of specific chemical compounds through a series of controlled reactions to produce the desired colorant.

- Scientific: Chemical reactions are carefully orchestrated to create the precise molecular structures that result in the characteristic red hue.

- Detailed: Each step in the synthesis process is meticulously monitored to ensure the purity and consistency of the final product.

- Informative: The color development is a result of the intricate manipulation of chemical properties, leading to the creation of a vibrant and stable red food colorant. This process highlights the innovative techniques used in modern food production.

This meticulous approach to red food color production underscores the importance of safety and adherence to regulations in the food industry.

Safety and Regulations

The production of synthetic red food color involves stringent adherence to safety protocols and regulatory standards to ensure the quality and purity of the final product.

- Safety standards, such as those set by the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA), govern the production process, ensuring that the color additive is safe for consumption.

- Regulatory compliance is essential in every step, from the sourcing of raw materials to the final packaging of the synthetic red food color.

- Manufacturers must meticulously follow Good Manufacturing Practices (GMP) to guarantee the safety and integrity of the product.

- Additionally, thorough documentation and traceability measures are implemented to uphold these safety and regulatory standards, providing transparency and accountability throughout the production process.

Applications in Food

- The production of synthetic red food color involves chemical synthesis or extraction from natural sources, followed by purification and formulation.

- Color stability: Synthetic red food color is designed to withstand various food processing conditions such as heat, light, and pH changes, ensuring its stability in the final food product.

- Consumer preferences: Manufacturers consider factors like hue, intensity, and application suitability, aligning with consumer preferences for vibrant and appealing food products.

Quality control and regulation play a crucial role in ensuring the safety and compliance of synthetic red food color for use in the food industry.

Quality Control and Regulation

Quality control and regulation standards are established to ensure the safety and quality of red food color production.

- Stringent quality control measures are implemented throughout the production process to meet industry standards.

- This involves meticulous monitoring of raw materials, production equipment, and final product testing.

- Industry standards dictate the permissible levels of contaminants, ensuring the product’s safety for consumption.

- Regulatory bodies such as the FDA and European Food Safety Authority enforce these standards, conducting regular inspections and audits to verify compliance.

- Advanced analytical techniques, including high-performance liquid chromatography (HPLC) and mass spectrometry, are employed to assess the purity and composition of red food color.

- Additionally, manufacturers adhere to Good Manufacturing Practices (GMP) to guarantee consistent quality.

Continuous innovation in quality control methodologies ensures that red food color meets the highest safety and quality standards.

Application of Red Food Color

Stringent quality control measures and regulation standards ensure the safety and quality of red food color production, impacting its diverse applications in various food and beverage products.

- Color Psychology: Red food color is strategically used to evoke specific emotions and appetites in consumers, such as passion, excitement, and hunger.

- Culinary Trends: Red food color is extensively utilized in modern culinary trends to create visually appealing dishes, aligning with the growing consumer demand for aesthetically pleasing and Instagram-worthy foods.

- Innovation in Product Development: Food manufacturers are continually exploring innovative ways to incorporate red food color into new products, leveraging its psychological impact and aligning with evolving culinary preferences.

Innovations in Red Food Color Production

With the advancement of technology and scientific research, innovations in red food color production have revolutionized the food and beverage industry.

- Sustainable alternatives, such as natural pigments from sources like beetroot, have gained traction due to consumer demand for cleaner labels and environmentally friendly products.

- These alternatives not only reduce the environmental impact but also offer vibrant and stable color options.

- Advancements in biotechnology have led to the development of microbial fermentation processes for producing red food colorants, offering a more sustainable and efficient approach.

- Furthermore, nanotechnology has enabled the creation of nano-sized red color particles, providing improved dispersibility and color intensity in food products.

These innovations reflect a shift towards more environmentally conscious and technologically advanced methods of red food color production, meeting the demands of a rapidly evolving market.

Conclusion

The production of red food color involves extracting and concentrating pigments from natural sources or synthesizing them through chemical processes.

Quality control and regulation ensure the safety and efficacy of red food color products. Innovations in production methods have led to more sustainable and efficient processes.

In 2018, the global market for food colorants was valued at $2.5 billion, with red food color being one of the most commonly used additives in the food industry.